THE first Chinese maglev train, capable of 600 km/h, has been completed at CRRC’s plant in Qingdao, Shangdong province and will now undergo several years testing before entering service.

Work to build new high-speed maglev infrastructure has yet to start in China although several lines have reached the research and assessment stage, including Shanghai – Hangzhou and Chengdu – Chongqing, which could offer hugely reduced journey times; CRRC says journeys between Beijing and Shanghai, which currently take almost five hours, will be almost halved to two and a half hours.

Two low-speed lines are under construction in Qingyuan, Guangdong province, and Fenghuang county, Hunan province.

Standard metro train

CRRC also unveiled a new Chinese standard metro train technology platform at the end of June. The platform includes four types of train: 80km/h Type A and B cars and 120km/h A and B cars. Each model can be freely configured in terms of driving mode, power receiving mode, vehicle grouping and body contour to meet the specific needs of users.

The first train - a 120km/h Type B set - was developed by CRRC’s China Railway Sifang subsidiary for use on underground networks. The train is fitted with GoA 4 level full automation. Development of the other three platforms is underway.

These trains have independent intellectual property rights, according to CRRC. There will be a generalisation of components that will be interchangeable depending on the specific needs of different lines, models of train and manufacturers. This is designed to reduce both the cost of operation and maintenance.

The trains have more than 250 component modules designed to achieve a modular design. This is intended to shorten the development cycle, meet customer needs more quickly, and reduce the cost of design, manufacture and maintenance.

CRRC says there is a core industrial cluster of more than 300 suppliers of parts and components that will guarantee the sustainable development of the urban rail industry supply chain.

For performance, CRRC says the noise inside the train is reduced by 2-3 decibels. The trains save 10% of the energy they use and will record a 10% reduction in the failures compared with existing trains, while CRRC says they will record a 20% increase in maintenance efficiency. It says the average operating fault-free interval mileage of the train is increased by 50%.

Inter-city train

On June 30, the CRH6F-A 160km/h inter-city train for the Jintai Railway suburban train project was delivered to the CRSC subidsary by CRRC. It will enter traffic in Taizhou, Zhejiang province, this month. These are based on the CRHA6 high-speed trains

The inter-city fleet will use surplus capacity on the Jintai Railway on the inner section of Taizhou City. It is planned they will operate on two lines from Xianju South Station – Taizhou West Station and Linhai East Station - Toumen New Station. This will total around 103km.

The train has capacity for 684 seated passengers in four cars, and can carry up to 918 passengers. The interiors are designed in a 2+2 layout while the seat pitch is 10.5cm wider than earlier trains. Seats are fitted with a charging socket and USB port.

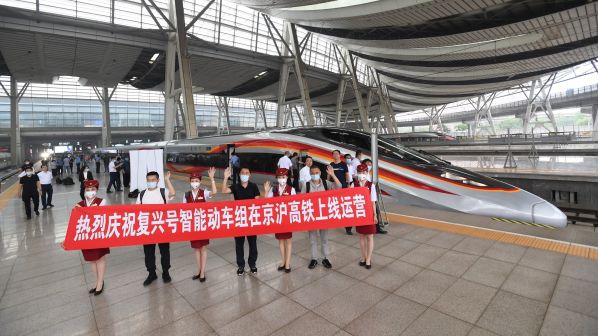

Fuxing high-speed train

On June 25, the latest iteration of the Fuxing high-speed train developed by CRRC Sifang debuted on the Beijing - Shanghai high-speed railway, completing the journey in 4h 37min.

These new trains are based on the existing 350km/h CR400AF platform but feature big data collection capability, 5G and cloud computing. They are also used on the Chengdu - Chongqing high-speed railway.

The new Fuxing trains are delivered in two configurations - the CR400AF-Z which is an eight-car formation or the CR400AF-BZ, which is the 17-car variant. They feature business class, first class and second-class accommodation.