THE majority of rail infrastructure is from a pre-digital area. Track maintenance is focused on preventative actions and ensuring optimum operating conditions by regular track walks and regular inspection of equipment and the historic use of consumables, but the very scale of the track infrastructure poses huge limitations on what can be achieved. Experience and best practice work to an extent, but nothing compares with real-time performance analytics generated by digital solutions. These provide the opportunity to set KPIs for maintenance teams and operators on which to measure value return.

However, a big challenge facing the railways is connecting non-connected assets with network enabled equipment. So how do we manage connectivity in these cases and how do we provide analytics that are useful to customers and network operators?

It’s widely recognised that breakthrough technologies applied to all aspects of the railways - from remote performance monitoring of trackside and on-board friction management to digital asset monitoring and digital asset maintenance - are releasing real lifetime value through proactive and preemptive asset management.

L.B. Foster has developed a range of intelligent digital solutions that enable traditional products, such as our track side PROTECTOR® series including PROTECTOR IV and PROTECTOR X friction applicators, to provide detailed performance data via email, SMS, and 3/4G connectivity. Sensors monitor when trackside consumables are getting low so that preemptive maintenance can be carried out.

Total Track MonitoringTM by L.B. Foster creates a smart interface between conventional rail products and intelligent performance monitoring digital technologies, delivering always-on data that improve asset performance, drive cost efficiencies, enhance safety, and assist security. When combined with our Total Track ManagementTM portfolio of high-performance track products integrated with our market leading onboard and trackside friction management solutions, the combination delivers extended asset life and improved asset performance.

Moving away from manual

In the past, rail track and infrastructure maintenance have relied on timely preventative interventions, such as walking the track and having a historic understanding of the use of consumables. The thousands of kilometres of track and unpredictable performance of assets can make this approach both arduous and inaccurate.

The move by train operators to run more services closer together continues to gather momentum. The need for a safer and more reliable approach is driving the adoption of new, smart technologies that remove the manual aspect of operating the railways, providing data and analytics on which to base informed decisions and investment.

Remote Condition Monitoring

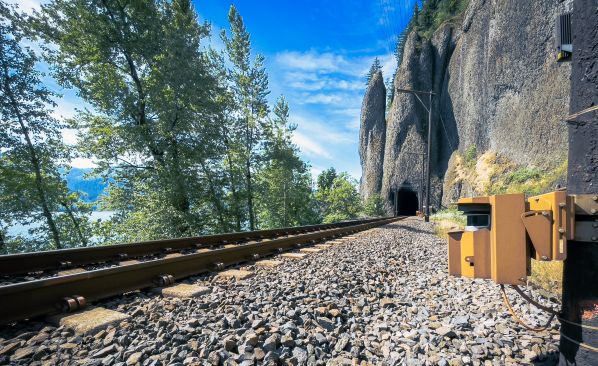

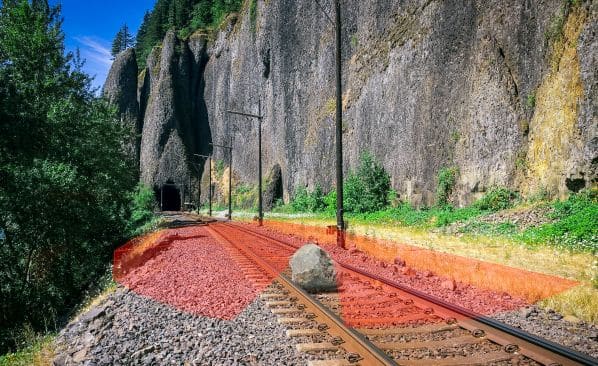

L.B. Foster’s range of smart monitoring solutions covers a diverse collection of rail operating and safety condition challenges. We have smart solutions that tackle condition challenges such as rockfall, flood, avalanche, and embankment, to the protection of physical assets such as bridge strike and level crossings. In addition, our smart sensing technologies are applied to monitoring maintenance cycles of trackside friction management, wheel load impact detection, wheel sensing and security surveillance.

Data from remote monitoring solutions is fed back to a central server. This allows operators to interrogate information to determine actions, as well as being able to build profiles of behaviours and events and take necessary actions.

L.B. Foster’s Rockfall Monitoring solution utilises LiDAR technology to detect rockfall and whether it remains an obstacle on track, size, and its position in the zone susceptible to rockfall.

Data gathering and analytics

Monitoring the performance and operating condition of assets across the network requires that our solutions can be addressed remotely via IP networks, 4G/5G networks, and trackside telecoms. Analysis of this critical information by maintenance, infrastructure management, and network operating teams shape decisions about when, where, what, and how to target expenditure and resources. In addition, it is imperative that the data we supply has a seamless interface with existing railway control systems.

Low energy and solar power

Alongside our smart digital solutions, we use several innovative low energy battery technologies, as well as rechargeable solar powered options such as CCTV. This means that once in the field, our solutions keep on working, delivering mission critical data that saves costs and enables informed operating and maintenance decisions. The always-on power source ensures that network owners and train operating companies can operate continuously.

The overarching benefits of proactive maintenance include advance scheduling of train and track maintenance, with spare parts warehoused in a timely manner. Individual assets can be better monitored to predict consumable needs and maintenance requirements. This promotes a smoother running railway, allowing higher density of train set on track utilisation and delivering better passenger satisfaction and better rail cost return, whilst reducing the number of major infrastructure critical failures. In addition, this promotes better budget planning and future upgrades, and ultimately better passenger experience and overall safety.