The investment follows the order for 13 Sapsan trains by RZD in June 2019, which took the total fleet to 30 sets and includes a 30-year maintenance agreement. The 3D printers are installed in St Petersburg and Moscow and will be used to produce replacement parts on-demand and used as part of Siemens’ ‘Easy Sparovation Part’ strategy to offer 3D printing and a digital inventory of original train components. Siemens is targeting 99% fleet availability for the Velaro trains.

“The manufacturing and delivery of an additional 13 Velaro trains will see us work on multiple vehicles over a long period of time and within very strict time constraints,” says Mr Alexey Fedoseev, head of customer services at Siemens Mobility Russia. “We have already seen the success of the Siemens Mobility ‘Easy Sparovation Part’ business in Germany, where this technology has provided us with time-per-part savings of up to 95% compared with traditional manufacturing methods.”

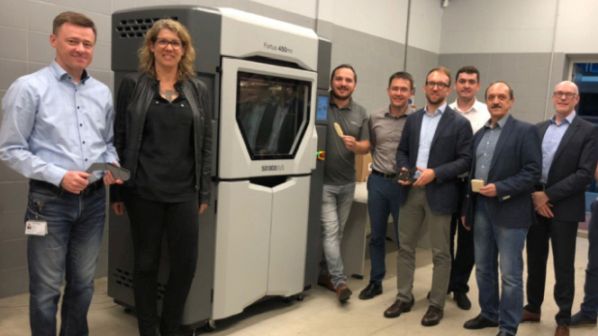

The Fortus 450mc machines will enable Siemens to print parts using industrial-grade materials with highly durable properties which are suitable for Russia’s extreme climate. In addition, by storing all part data online, Siemens is able to access and replace train components ad-hoc and meet stringent maintenance time limits.