The bench will help to ensure the reliable performance of transmissions and gear units in conditions ranging from -50°C to +85°C, and will also allow resistance to mechanical factors, ice buildup and strong headwinds of up to 50m/s (180km/h) that relate to driving speeds of 360km/h to be tested. In addition, the test bench is suitable for load testing and endurance runs with continuous operation of up to 24 hours, seven days per week. A high level of automation also allows the simulation of real driving cycles.

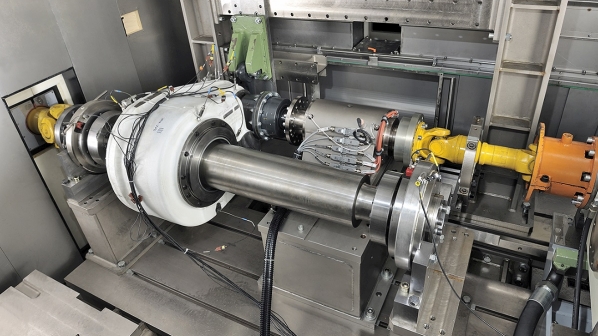

Installed at the company’s headquarters in Heidenheim, Germany, the bench is designed for four-quadrant operation and ensures traction and braking testing of hydrodynamic and hydromechanical transmissions as well as gear units for EMU applications.

Type testing in accordance with individual customer requirements is possible as well, and Stadler Rail is one of Voith’s first customers to test a gear unit on the new bench.

Due to its acoustic design, the bench provides grade 2 accuracy measurements of sound power levels in accordance with DIN ISO 3744. The bench achieves a nominal capacity of 1.9MW with an input torque of 15kNm at 8000 rpm and an output torque of 60kNm at 4000 rpm. In addition, the CE-certified test bench has an overload capacity of 3400kW, enabling demanding testing procedures and a great range for highly dynamic simulations. The drive is height adjustable and can be positioned at a 90o angle to accommodate bevel gears.

The test bench’s four-quadrant operation helps to effectively minimise energy costs. Energy efficiency is further improved by its cooling unit, which actively recovers heat for reuse.