HITACHI Rail has launched Train Maintenance DX as a Service, what the Japanese manufacturer claims is the railway industry’s first “as a Service” solution for train maintenance.

Aimed at train operators across the globe, the new service promises to simultaneously improve the quality of train maintenance and the operators’ work environment. It will do this by combining both hardware and software expertise developed at Hitachi Rail’s Kasado works in Kudamatsu City, Japan.

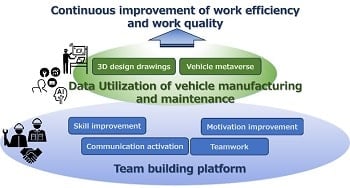

The service is designed to integrate digital expertise in train manufacturing with IT solutions for team building and production improvement DX (digital transformation), which will in turn increase work efficiency and quality and also improve teamwork and motivation levels at maintenance depots.

Train Maintenance DX as a Service aims to modernise train maintenance procedures by digitising paper-based management systems and replacing on-the-job technical training with easily distributed digital toolkits.

Hitachi says that the company has developed a team-building platform that allows all team members to visualise their whole work environment, which allows them to respond quickly and dynamically to changes in circumstances, including delays in arrival of trains for maintenance and short-term labour supply issues.

Hitachi adds that the platform could potentially unlock skills and expertise that had previously been limited to individuals or teams within a specific maintenance depot by enabling information sharing across the whole workforce, improving communications and team motivation.

Hitachi adds that it expects Train Maintenance DX as a Service to make train maintenance more efficient by using AI-based automatic inspection technology to identify failing components before they fail and by utilising 3D drawings in the vehicle metaverse which were originally developed to assist the manufacturing process.