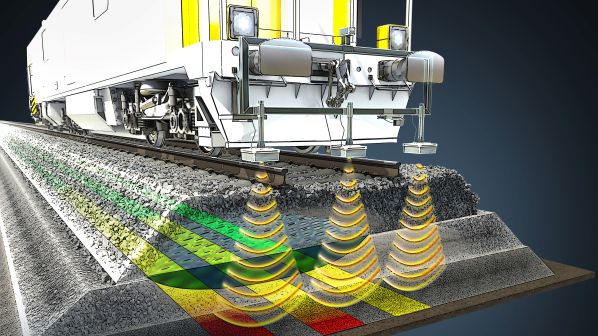

IN view of the advantages GPR offers, Plasser & Theurer says the next logical step is to combine it with other measuring systems, as testing with the EM100VT carrier vehicle has shown. A single measuring run not only provides outer track geometry data, it also allows for a detailed insight into its “inner values.”

GPR can be used for preventive inspections, is a useful addition to track maintenance machines, and is used for documenting track renewal work such as the installation of a formation protective layer. In addition, GPR data helps planning for ballast cleaning and track renewal machines.

Plasser & Theurer says there is great potential in incorporating GPR into track maintenance machines, which is why it has initiated a technology partnership with Ground Control, a technology leader in the field of GPR in track maintenance.