THE global rail renaissance has spawned major new-build and upgrade projects in many countries. They tend to be highly complex and must usually be completed to tight schedules despite constraints on financial resources. Planning and implementing major projects requires highly effective collaboration between teams working in many different countries.

Equally essential is efficient processing of the information required for data-driven decision-making. At Siemens Mobility we are working to provide end-to-end transparency across all processes, which are logically connected through a holistic data model. Making this vision a reality requires not just sophisticated technology, but also a very particular approach to the way of working and how data is generated.

Building Information Modelling (BIM) has proven to be a very useful way of managing large infrastructure projects in the construction industry. BIM makes fully virtual project planning possible, taking in all relevant interfaces and information flows. This “build digital first” approach paves the way for improvements in both the quality of planning and the management of the actual construction phase. The accumulated data remains available for the maintenance phase and, eventually, can be used for planning modernisation and upgrade work. This helps to optimise maintenance processes from the outset and to more effectively plan and simulate future modifications, adding value throughout the lifecycle of the project.

Multi-dimensional BIM

Siemens Mobility has defined a framework for implementing BIM so that it can make efficient use of all the advantages of this methodology. The framework provides a comprehensive set of rules to ensure that BIM is integrated as effectively as possible within the company at the level of processes, policies, technology and competence development.

Workflows have been specifically tailored to rail projects. A dedicated guideline on configuration and use has been drawn up for modelling, coordination and the Common Data Environment (CDE) that houses project information, as well as the relevant processes for the development and coordination of comprehensive 3D design in BIM. This provides effective practical implementation of software solutions, ensuring that processes, roles and systems mesh together properly and operate smoothly.

Competence development has an important role to play in integrating the new way of working. Our extensive tri-level training landscape, which provides for the broad-based upskilling of all relevant process roles, has helped over 1000 employees enhance their capabilities. Internal processes are complemented by a strong focus on integrating external partners to optimise the sharing of information from the start and to establish common standards.

Managing rail infrastructure projects involves implementing a considerable number of different processes, many of which often run in parallel while being interdependent. Our BIM standard for mobility differs from the traditional BIM approach in one key aspect: it goes beyond 3D modelling of infrastructure to furnish the basis for a complete digital twin. This makes it possible to factor in all aspects of a project before and during construction, and to draw conclusions during the project thanks to end-to-end data integration. All of the parties involved are able to perform consistency checks to analyse how planning and construction can be expected to proceed and how best to eliminate sources of error before they materialise.

Links and interfaces in rail projects have generally been managed manually in the past, which involves a substantial amount of coordination work. Making changes is also more complex, because of the dependencies between processes and data points. Siemens Mobility has set out an approach in which fully integrated data enables more strongly data-driven insights to be obtained faster and with greater precision. Identifying the implications of process changes in the absence of fully integrated processes can often take hours or even days. Providing access to properly integrated data, however, makes the result of changes clear within seconds.

This level of transparency can only be achieved with a project-wide holistic data model for the digital twin that is applied to all the processes involved to integrate their data. Documents, schedules, requirements, interface management, configuration management, strategic procurement and installation management must all be included in addition to 3D models and geographical data.

Achieving such a high level of integration in practice necessarily entails defining data governance guidelines and ensuring they are adhered to. The underlying process here is information management, which focuses on aspects such as access to data, the structuring of data and ensuring consistent quality as well as data acquisition.

Siemens Mobility has demonstrated how this vision can be implemented, in terms of processes and technology, in a proof of concept on the Greater Copenhagen light rail project where it is delivering railway systems on a turnkey basis, from electrification and signalling systems to a fleet of 14 Avenio LRVs.

The case study focused on the stop at Glostrup, and whether it was possible to identify the result of changing the number and properties of switchgear cabinets at this location.

The changes determined from the configuration data had implications for design documents and requirements at the interface with the power supply. The changes could be visualised in the 3D model to investigate other potential consequences, such as the proper positioning of the modified switchgear cabinets.

Case study

The case study demonstrated that having all the process data properly integrated makes it feasible to track changes and their impact transparently. Situations and their implications could be identified rapidly without the laborious data-based research and impact analysis of individual processes that were previously required. Action could be taken quickly, driven by connected data.

One of the most significant findings from the proof-of-concept exercise is that having heterogeneous source systems is not so much of an issue if the information management process is applied. This is because data can be effectively decoupled from the original source systems when all data adheres to the data governance guidelines. This opens up the possibility of implementing a flexible, scalable data integration platform that can be transferred to other turnkey projects.

The benefits of deploying the PIB include the ability to track the implications of technical changes throughout the project management and system integration processes.

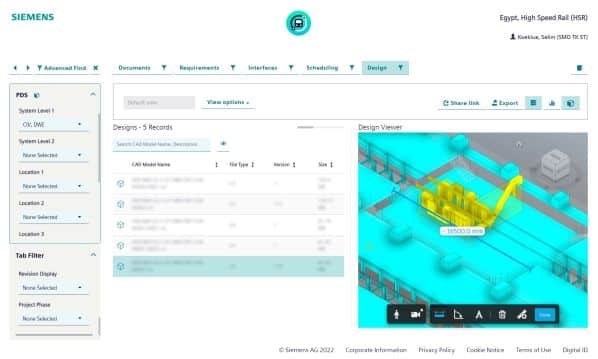

Building on the insights gained from the proof of concept, the Project Insight Board (PIB) was created as a data integration platform to provide a single source of project information. This involved establishing the requirements and then defining a suitable software architecture to fully integrate alphanumeric data, charts, map data and 3D models. With this advanced level of integration, PIB users can analyse data in different dimensions with no media discontinuity and no need to switch applications. Data integration is the foundation of a fully-integrated user experience. Users are able to navigate from alphanumeric process data to other linked process data, review data on a map, pull up charts for analysis and complete technical checks in a 3D model. Loss of context is never a problem because all process dependencies and changes are indicated with precision.

Documents are a good example. Detailed information, related documents, underlying customer requirements, interfaces, approval status and document comments can all be analysed in a single view with just a single click. When it comes to validating requirements in the 3D model, users can switch directly from a document to a requirement and eventually to the linked 3D model to complete a technical check. All information provided for users is quality-assured, so they can concentrate purely on the content and what it means for the project.

This complex data integration is performed using multi-dimensional knowledge graphs that consider different data sources and corresponding time information. The holistic data model from the information management process is used as the basis here, so every data entity in every process knows to which system and location it belongs and information can be grouped accordingly. In addition, unique identifiers are used to create direct links between closely intermeshed processes to ensure no gaps remain in the information chain. Any missing data connections are filled by links that are determined either semantically or identified by machine learning, neither of which could be produced manually no matter how significant the resources dedicated to the task.

Efficient cooperation requires not only data integration, but also widespread use of the solution by the project team. Teams spread across a number of different locations face a particular challenge in maintaining a common view of relevant data. A data integration platform that considers only individual user needs cannot satisfy today’s requirements. The PIB changes over the course of every project and lends itself to being used by the project team in a collaborative manner. Best practice in analysis can be shared within the team quickly and easily, or permanently implemented on a project-wide basis if it is considered to provide a standard for a particular analysis. Thanks to its analytical strengths and collaborative aspects, the PIB also facilitates data-driven discussions of technical issues between all parties involved in the project, from engineers to business management.

Egyptian high-speed

Last summer Siemens Mobility put the initial version of its PIB to work on the high-speed rail project in Egypt, where it is working with consortium partners The Arab Contractors and Orascom Construction to design and build a 2000km network that will connect 60 towns and cities across the country, handling 35 billion passenger-km a year. The turnkey project encompasses the entire rail infrastructure, as well as 41 high-speed trains, 94 regional trains and 41 locomotives plus a 15-year maintenance contract. Fittingly for a high-speed railway, the project also requires high-speed delivery on the part of the contractors.

Some 200 to 300 project staff will be using the PIB, but this will not interrupt its development. The intention is to carry on expanding its functions continuously to improve and extend end-to-end transparency throughout the project. The benefits of deploying the PIB include the ability to track the implications of technical changes throughout the project management and system integration processes. Without data integration, five separate data sources would have to be used and manually evaluated in parallel.

Simplified access and the proper integration of information using the PIB also reduces information loss and very significantly increases the reliability of information across the different phases of the project, from design to installation and operation. This also helps to reduce the number of potential technical changes required. In addition, the PIB enables more efficient monitoring of the implementation of contractual requirements, taking account of all relevant processes, and the automation of reporting provides efficiency gains in day-to-day project work.

Advanced data integration through a sophisticated software architecture has been made possible by the PIB, which combines BIM with the information management standards developed by Siemens Mobility.

Project management of complex rail projects is going to change significantly over the coming years. The PIB data integration platform will not only deliver dramatic improvements in the speed and effectiveness of many processes, but is also intended to generate new project insights automatically to help with the management of complexity.

In addition, the PIB will help to reveal errors before they have an impact on the project and assist the project team in both operational business and planning. In future, AI-based forecasts of consequences in the PIB will also help guide project management. Ongoing project work is expected to provide additional impetus for holistic data integration that should make the PIB even more effective and further enhance its ability to create value in the long term. This fits in very well with Siemens Mobility’s broader objective of not just realising measurable added value for all project participants, but of finding a faster route to delivering sustainable mobility.

*Selim Köklü is digitalisation lead, Fabian Skalski, solution architect, and Mehmet Kara, requirements engineer, at Siemens Mobility.